It may be surprising to learn that many engineers with great talent and a depth of experience have a hard time answering questions regarding the type(s) of manufacturing environments that exist in their company. Hopefully, this article will help practitioners to better categorize what often appears to be shades of gray.

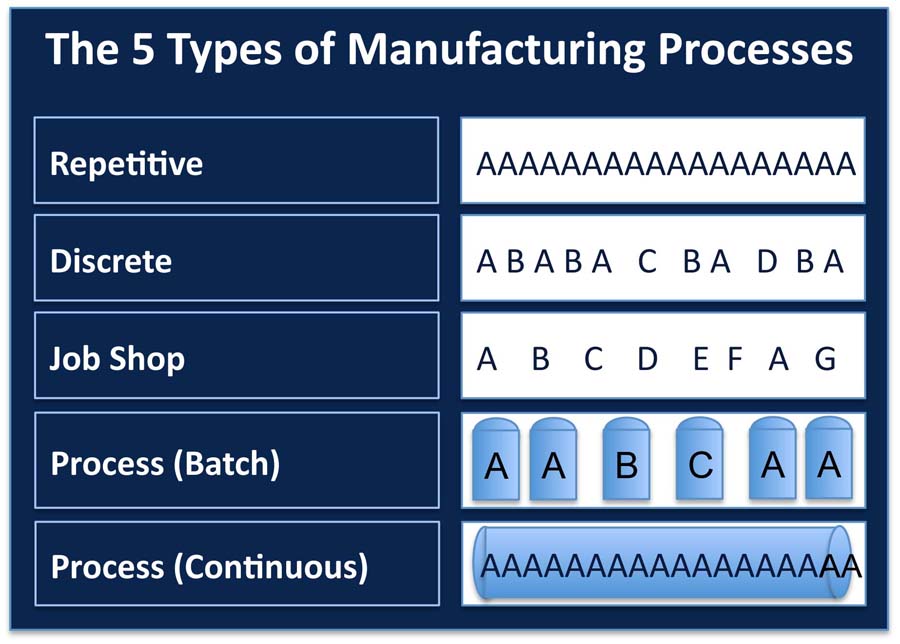

Most manufacturing environments fit into one of five general categories: Repetitive, Discrete, Job Shop, Process (batch), and Process (continuous).

In the diagram below, each letter represents a different product. “White space” indicates set-up, tear-down, or a changeover activity of some type. Product is not being produced when there is white space. Some white spaces take longer than others. The white space time depends on both the clean up time for the product just produced and on the preparation time for the next product to be produced.

Most companies use more than one of these environments to get a single product out the door. This is certainly true if one includes today’s use of the supply base, versus the historical practices of vertically integrated companies. One of the factors that drove the outsourcing movement was that vertically integrated companies often had all five environments in house, and the associated expense to maintain proficiency across this broad spectrum.

The 5 Types of Manufacturing Processes [Machine Design – September 2015] describes each of the five distinctive manufacturing environments, and the similarities and differences between them.

![Goldense Group, Inc. [GGI] Logo](https://goldensegroupinc.com/blog/driving-product-development/wp-content/uploads/2022/03/logo-corp-darkBlue-65x65.png)

It’s cool to learn more about these different manufacturing processes. I like how you said that the white space in your graph is set-up, tear-down, or changeover time. What about the time for inspections, or things like that? Isn’t that a part of the manufacturing process?