Does your company tightly control its manufacturing operations and work centers? If so, each work center is measured and the company knows exactly how much good and bad product the center produces. These figures are the center’s “yield.” Of course, companies aim for 100% positive yields from each center. And, products which have been manufactured for a long time often approach that ideal.

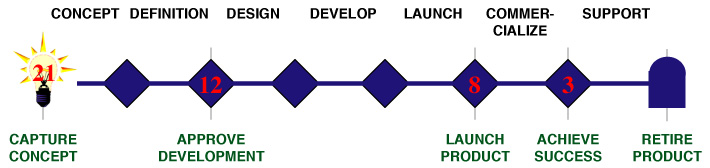

Now, let’s take this same basic concept of a center’s yield and apply it to product development. There are series of centers that take new product concepts and bring them to market. But for these, 100% yields are not expected, nor would we wish them to be. Product development is much more probabilistic. Not every product brought to market is expected to be a financial success. If it were, innovation would dry up as companies would take no risks.

Many studies over the past five decades have found that somewhere between 35% and 55% of products are not financial successes. That figure can be as high as 90% in high-tech and consumer products. Those high failure rates create an opportunity to improve yield without risking the loss of innovation.

New Product Pipeline Yield Example

There are opportunities in most companies to get more revenues and profits from the product pipeline without increasing investment or headcount. Those opportunities have one common element, better decision making.

Maximizing Revenues from the New Product Pipeline [Machine Design – May 2015] discusses decision making in corporate environments that have too many ideas to choose from, too few ideas to choose from, and the financial results of both good and bad pipeline management. Bettering management of the pipeline often results in double digit percentage increases in revenues and profits from new products.

![Goldense Group, Inc. [GGI] Logo](https://goldensegroupinc.com/blog/driving-product-development/wp-content/uploads/2022/03/logo-corp-darkBlue-65x65.png)